Welcome to GABION SUPPLY

GabionSupply.com is part of BlueStone Supply LLC, an easy to navigate e-commerce portal for civil construction products. Check out our site today! BlueStoneSupply.com

GABION SUPPLY is one of the few American Owned and Managed suppliers of DURABLE GABION BASKETS, GABION "RENO" MATTRESSES, GABION ROCK FENCES and GEO-TEXTILE PRODUCTS

WE OFFER THE WIDEST RANGE OF GABIONS - ALL TYPES & ALL SIZES

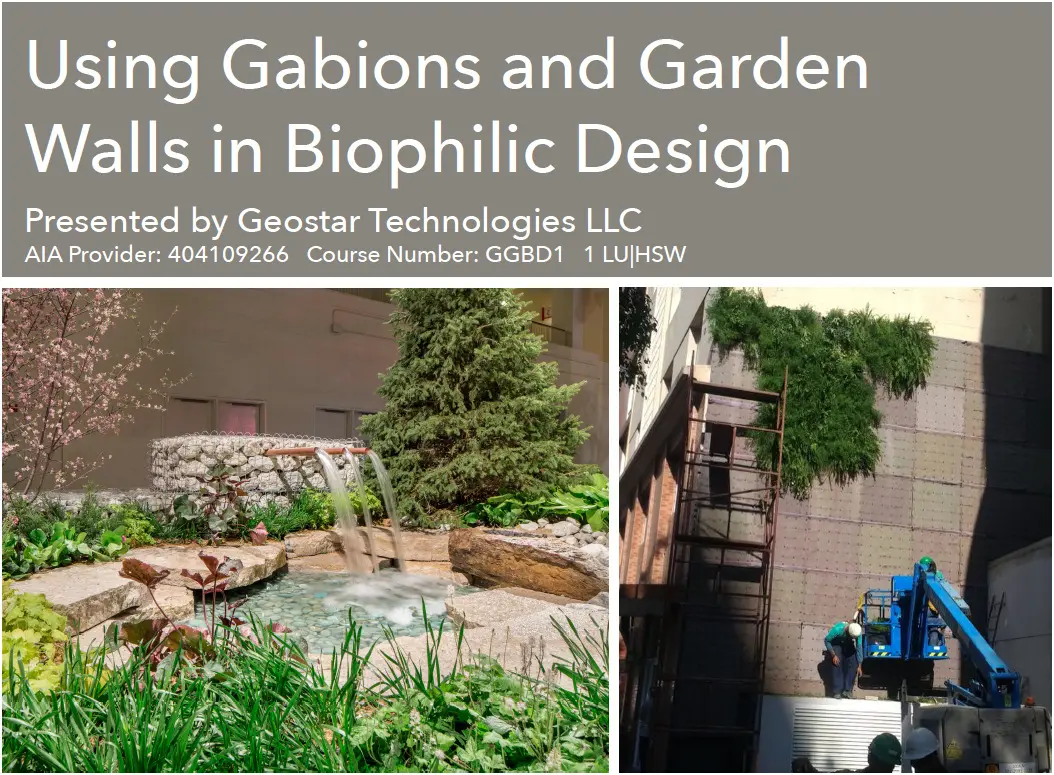

Gabions, from the Italian word for cage, are strong containers filled with inorganic materials like rock, concrete, sand and soil and in certain architectural applications glass rock. These cages are constructed of site specific material including galvanized steel, stainless steel, raw steel, PVC coated steel, and copolymer plastic. They are designed to withstand all kinds of weather and site conditions and are known for their incredible versatility.

Gabions are very useful in civil engineering, military applications, road building, general landscaping elements, foundations, erosion control, and architectural elements. Some of the fastest growing applications of gabions include architectural fence and veneer construction and for stabilizing shorelines against erosion since they form flexible and permeable structures.

Gabion Supply is proud to be one of the few American owned and managed suppliers of durable gabion baskets, gabion “reno” mattresses, gabion rock fences, and geo-textile products. We sell gabion baskets and green wall systems for a variety of civil construction and

architectural products. We’re proud to offer the widest range of high-quality gabions, all types and all sizes including custom-made gabions.

Permeable

Gabion walls are known for their permeability. This means that they need less drainage and in some cases no additional drainage behind the face of the wall due to less hydrostatic pressure buildup.

Sustainable

Gabion walls are sustainable because they are filled with minimally processed stone, a natural resource that can be sourced locally. If desired and with the proper maintenance vegetation can grow so the gabion walls can blend into the environment. Moreover, gabion retaining walls have a lower carbon footprint than traditional concrete retaining walls of the same size in terms of CO2 emissions.

Durable

Our gabion walls are designed to last since they’re flexible and are able to move with the earth. Unlike stiff materials like concrete which can crack as the years go by, gabions can move and settle with the natural movement of the earth.

Explore all your options with our wide range of standard and custom American made gabion products. A variety of material and finishes are available including, galvanized steel, galvanized steel with PVC coating, Galfan, stainless steel, and plastic copolymer.